Ride-on Skid Steer Loader Instruction Manual

SDLL580

Table of contents

| 01. Product Overview | 05. Operating Procedures |

| 02. Main Technical Parameters | 06. Routine maintenance and upkeep |

| 03. Safety Precautions | 07. Disclaimer |

| 04. Equipment Structure | 08. Common Problems and Solutions |

Product Overview

It is a multi-functional small engineering machine, characterized by its compact size, flexible steering, and high operating efficiency.

By quickly changing different working attachments (such as buckets, breakers, log grapples, etc.), multiple operational functions such as digging, loading, transporting, crushing, and cleaning can be achieved.

It is widely used in construction, municipal engineering, agricultural production, mining, warehousing and logistics and other fields.

Main technical

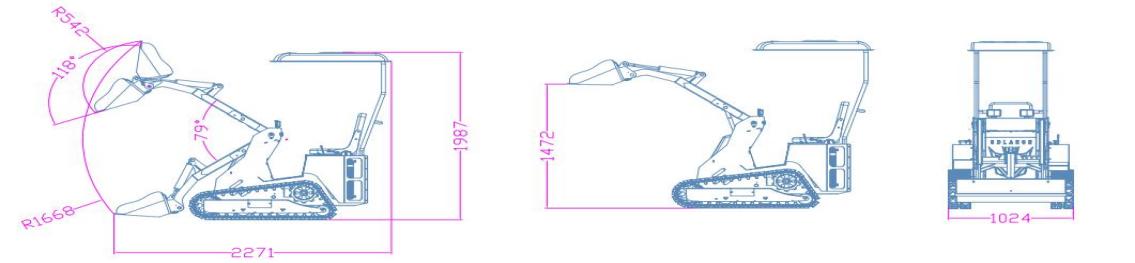

| Dimensions (mm) | 2640*1024*1987 | Minimum turning radius (mm) | 1200 | Maximum lifting height (mm) | 1472 |

| Engine | Runtong 420 | Engine power (kW) | 8.6 | Maximum engine speed (rpm) | 3600 |

| Fastest speed | 3.9 km/h | Maximum climbing angle | 30° | Bucket volume (m³) | 0.09 |

| Fuel volume (L) | 6.5 | Hydraulic oil volume (L) | 12 | Hydraulic oil type | 46 |

| Maximum flow rate (L/h) | 6 | Rated pressure (MPa) | 25 | Maximum lifting angle | 79° |

| Track specifications (mm) | 180*72*37 | Track material | rubber | Operating weight (kg) | 950 |

Safety Precautions

1. Inspect the tracks Check the equipment's appearance for any damage, deformation, or leakage. Pay special attention to the wear and tension of the tracks, and ensure that bolts, nuts, and other fasteners are secure.

2. Check the liquid. Check whether the levels of fuel, engine oil, coolant, and hydraulic oil are within the specified range and whether the oil quality is normal. If they are insufficient, replenish them in time. If the oil quality is deteriorated, replace it in time.

3. Check the system Check the braking, steering, and hydraulic systems for proper functioning; ensure the brake pedal travel is appropriate; check the steering for smooth operation; inspect the hydraulic lines for leaks; and verify the connections are secure. Also check the electrical system, including ensuring the battery is fully charged; and verify that the lights, horn, instruments, and warning lights are functioning correctly; and check for any damage or aging in the wiring.

4. Attachments Check whether the working attachments (such as the bucket) are securely installed, whether the connecting pins and locking devices are reliable, and whether the attachments are damaged.

Equipment Structure

This skid steer loader mainly consists of an engine, chassis, hydraulic system, operating system, working device, electrical system, etc.

( 1 ) Engine: The power source of the equipment, providing power for the equipment to travel and operate.

( 2 ) Chassis: including frame, tracks, drive system, braking system, steering system, etc., supports the main body of the equipment and enables the equipment to drive, steer and brake.

( 3 ) Hydraulic system: It consists of hydraulic pump, hydraulic motor, hydraulic cylinder, hydraulic valve, hydraulic pipeline, etc., and controls the lifting, tilting and moving of the working device and the equipment.

( 4 ) Operating system: including operating handles and switches, for operators to control the operation and work of the equipment.

( 5 ) Working device: including connecting frame and various working accessories (such as bucket, breaker hammer, etc.), which are the components that realize specific operation functions.

( 6 ) Electrical system: including batteries, generators, lights, horns, instruments, control lines, etc., to provide electrical power and control signals for the equipment.

Operating steps

Pre-start checks

( 1 ) Inspect the appearance of the equipment to confirm that there is no damage or leakage, the tracks are in good condition, and the connecting parts are tight.

( 2 ) Check the levels of fuel, engine oil, coolant and hydraulic oil to ensure they are within the specified range.

( 3 ) Check the electrical system. The battery has sufficient power and the lights, horn and instruments are working properly.

( 4 ) Confirm that the working accessories are securely installed and the locking device is reliable.

Startup Operation

( 1 ) Turn on the mini power main switch.

( 2 ) Pull the damper cable.

( 3 ) Turn the accelerator to more than half.

( 4 ) Turn the key switch.

( 5 ) Close the damper cable.

Driving operation

( 1 ) Forward: Slowly push the driving control handles on both sides to the forward position, and the equipment will start to move forward. The greater the pushing angle, the faster the driving speed.

( 2 ) Reverse: Slowly pull the driving control handles on both sides to the reverse position. The equipment will start to reverse. The greater the pulling angle, the faster the reverse speed.

( 3 ) Turn left : Pull the left driving control handle back and push the right driving control handle forward to turn the equipment to the left; or reduce the pushing angle of the left handle and increase the pushing angle of the right handle.

( 4 ) Right turn: Pull the right driving control handle back and push the left driving control handle forward to turn the equipment to the right; or reduce the pushing angle of the right handle and increase the pushing angle of the left handle.

( 5 ) Turning on the spot: Push one side of the driving control handle to the forward position and pull the other side to the reverse position. The equipment can turn on the spot and is suitable for operation in narrow spaces.

( 6 ) Stop: Release the driving control handle, the handle will automatically return to the neutral position, and the equipment will decelerate and stop.

Routine maintenance and upkeep

( 1 ) Cleaning: Clean the surface of the equipment, removing dirt, debris, oil, etc., and clean the radiator, air filter, etc., to ensure good heat dissipation and clear instrument readings.

( 2 ) Check fluid levels: Check the levels of fuel, engine oil, coolant, hydraulic oil and brake fluid. If they are insufficient, replenish them to the specified level in time. When replenishing, use oil that meets the requirements. It is strictly forbidden to mix different types of oil.

( 3 ) Check for leaks: Check the pipelines, joints, seals and other parts of the engine, hydraulic system and braking system for fuel, engine oil, hydraulic oil and brake fluid leaks. If there are leaks, they should be dealt with in time.

( 4 ) Check the connecting parts: Check whether the track tensioning device, the connecting pins of the working device, the locking pins and other connecting parts are tight. If they are loose, tighten them in time.

( 5 ) Check the tracks: Check whether the track tension is appropriate, and whether the track plates are damaged or detached. If there are any problems, they should be dealt with in time.

( 6 ) Check the electrical system: Check whether the battery terminals are secure and corroded, whether the lights, horn, instruments, etc. are working properly, and whether the wiring is damaged.

Maintenance cycle | Maintenance items | Maintenance content |

50 hours | Engine oil and oil filter (first service) | Change the engine oil and oil filter. |

100/ hour | Air filter, fuel filter, engine oil and oil filter ( maintain approximately every 100 hours; the maintenance interval may be slightly extended depending on the color of the engine oil). | Replace the air filter, oil filter, diesel filter, and engine oil. |

200/ hour | Hydraulic oil and hydraulic oil filter | Check the hydraulic oil quality and replace the hydraulic oil and hydraulic oil filter. |

3 days / time | Add grease for lubrication | Every 3 days or so, apply grease to the area with the grease fitting for lubrication. |

Disclaimer

Our company assumes no responsibility for equipment damage, personal injury, or property loss caused by human factors such as failure to operate the equipment in accordance with this instruction manual, overloading, unauthorized modification of the equipment, or use of non-original parts. For equipment damage caused by force majeure events such as natural disasters (such as floods, earthquakes, lightning strikes), or accidents, our company does not provide free warranty service, but we can offer paid repair services.

Common problems and solutions

The machine cannot start (when there is no power).

( 1 ) Check if the vehicle is powered on normally.

( 2 ) Check whether the key switch is working properly and whether the wiring harness fuse is working properly.

The machine cannot start (while powered on.

( 1 ) Check if the engine oil and fuel are normal.

( 2 ) Check if the starter motor is working properly.

( 3 ) Turn the accelerator to more than half.

( 4 ) Check if there is oil backflow in the carburetor.

( 5 ) Check if the spark plugs are firing properly.

After starting, the car did not move.

( 1 ) Check whether the flow rate at the outlet of the hydraulic oil tank is normal.

( 2 ) Check whether the flow rate at the oil outlet of the gear pump is normal.

Some operations are not performed after startup.

( 1 ) Check if the valve core of the multi-way valve is stuck.

( 2 ) Check whether the hydraulic cylinder is normal and whether there is internal pressure.

( 3 ) Check if the pressure of the multi-way valve is normal.

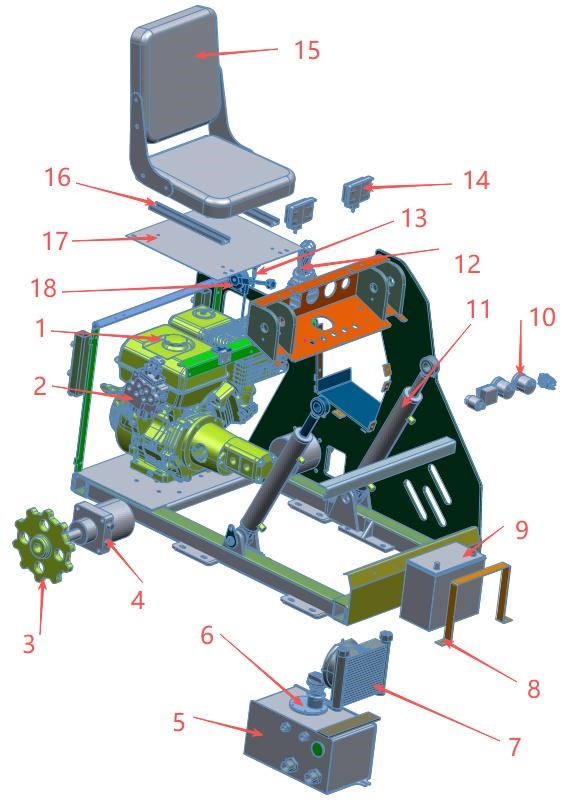

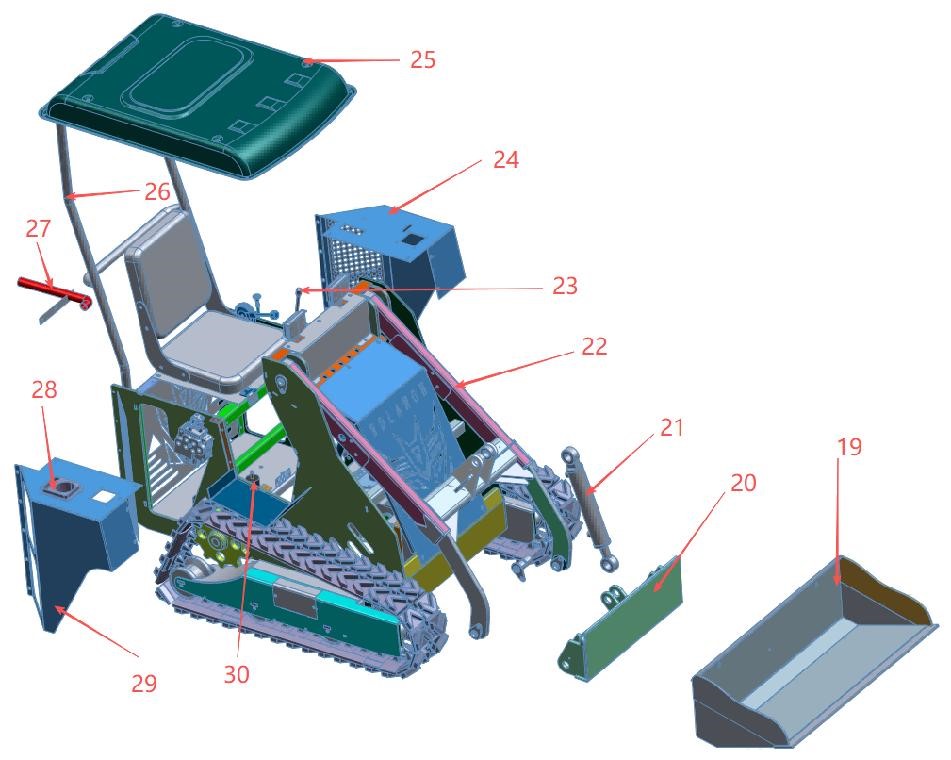

Product Parts Introduction

| 1. Engine assembly | 10. Electrical instruments |

| 2. Right dual valve | 11. Boom cylinder |

| 3. Drive wheel | 12. Left handle |

| 4. Travel motor | 13. Air damper cable |

| 5. Fuel tank assembly | 14. Two headlights |

| 6. Fuel tank cap | 15. Seat |

| 7. Hydraulic oil cooler | 16. Seat rail |

| 8. Battery clamps | 17. Seat cover |

| 9. Battery | 18. Throttle cable |

| 19. Bucket assembly | 25. Canopy |

| 20. Quick change | 26. Canopy support frame |

| 21. Reversing cylinder | 27. Engine tailpipe |

| 22. Boom assembly | 28. Cup holder |

| 23. Auxiliary handle | 29. Right side fairing |

| 24. Left guard | 30. Engine shock absorber |

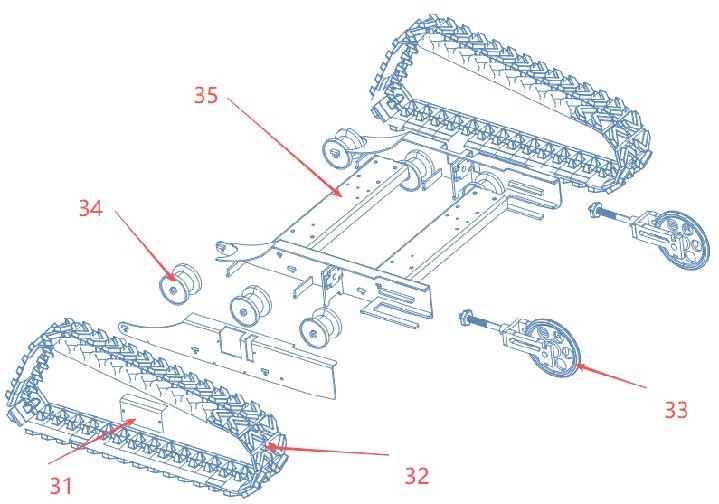

| 31. Undercarriage cover plate |  |

| 32. Rubber tracks | |

| 33. Guide wheels | |

| 34. Track rollers | |

| 35. Undercarriage frame |

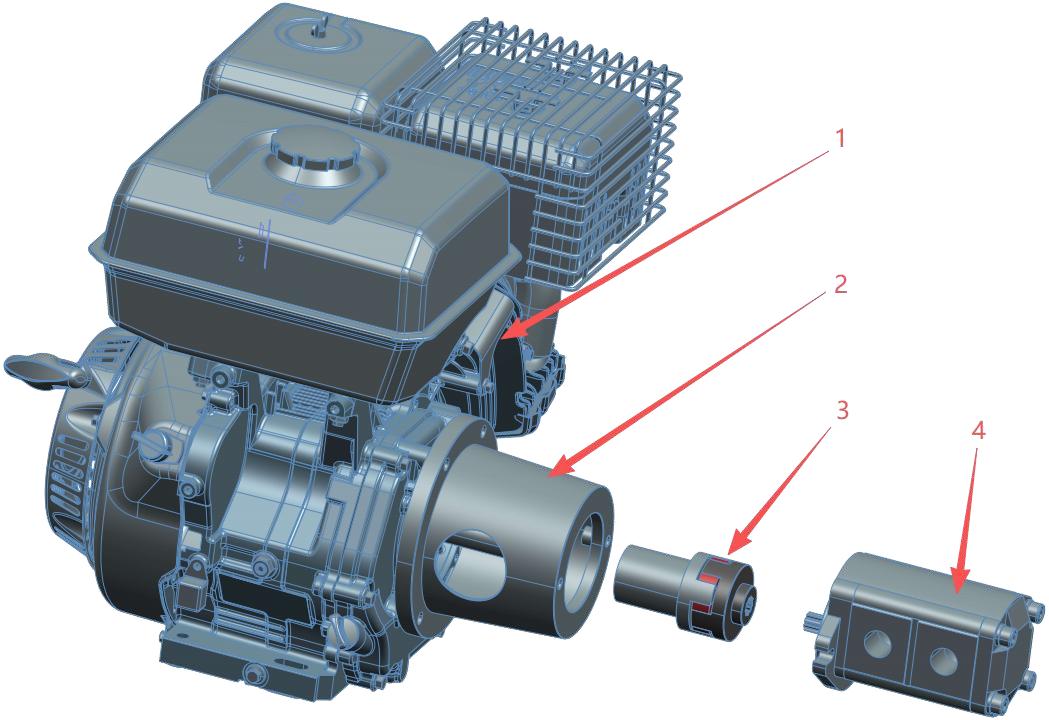

| 1. Engine assembly |  |

| 2. Bell-shaped cover | |

| 3. Coupling | |

| 4. Double gear pump |

| 1. Two large lights | 5. Horn switch |  |

| 2. Mini power switch | 6. Turn on the switch | |

| 3. Voltmeter | 7. Light switch | |

| 4. Timer | 8. Vehicle nameplate |